On September 22, 2021, the Emergency Management Department of Shandong Province issued the "Work Plan for the Construction and Application of Safety Production Informatization of Hazardous Chemicals in the Province (2021-2022)", which requires the promotion and application of safety production dual prevention mechanism information system, special operation whole process information management and video monitoring system, intelligent video monitoring system, enterprise safety production all factor management information technology, and gas station intelligent video monitoring system.

On December 28, 2021, six ministries and commissions jointly issued the "Management Measures for Construction Standards and Certification of Chemical Industry Parks (Trial)", which requires chemical industry parks to establish access control systems and video surveillance systems, and implement full process supervision on the entry and exit of materials, personnel, and vehicles such as flammable, explosive, toxic and harmful chemicals; A safety production monitoring and risk warning system should be established, and relevant data should be integrated into local monitoring and warning systems.

The trend of upgrading smart parks is inevitable, and traditional parks urgently need to be transformed

On the road to promoting industrial digitization and safety production informatization, smart parks have become an important direction for park construction and upgrading. Traditional parks, represented by chemical parks, face three major safety management pain points:

1. The on-site situation is complex, and manpower cannot achieve 24-hour supervision, making it difficult to ensure safety production.

2. The order of personnel management needs to be improved, and the foundation of safety management needs to be strengthened.

3. The degree of digitization in security management is not high, the "information island" has not been resolved, and the emergency closed-loop has not yet been formed.

Promoting the informatization and intelligence of safety production and building smart parks has become an inevitable trend.

Comprehensive upgrade of chemical industry park: Minivision AI, full escort

Minivision focuses on video surveillance construction, creating a "smart park solution", improving the management of all elements of safety production, and building a systematic, safe, and visual smart management system for it.

Strengthening security measures in key areas to ensure safe production

The intelligent monitoring distributed throughout the park constitutes a "multiple line of defense", which monitors the entire elements and process of safety production, assists in hazard investigation and governance, and tracks the entire process.

Chemical Industry Park · Safety Helmet Testing

After being enabled by the Xiaoshi AI algorithm, the camera can actively identify violations such as leaving work, non-standard work attire, and area crossing/intrusion; Real time monitoring of vehicle access and operation progress in the entry and exit channels and loading and unloading areas; In areas strictly prohibited from smoking, making phone calls, flames, smoke, and other safety hazards, achieve a "second level response".

For key areas such as warehouses and loading and unloading docks with major hazardous chemical sources, as well as special operations such as hot work, blind plate plugging, and earth breaking, video monitoring can be strengthened and key arrangements can be made.

Chemical Industry Park · Flame and Smoke Detection

Real name system for senseless passage and more standardized personnel management

Minivision facial recognition equipment can be linked with the access control system and has functions such as ID verification. The real name system for park personnel is implemented, and employees can pass through without feeling through facial recognition.

By collecting personnel information and traffic data, equipment can uniformly control and classify personnel entering and exiting production areas and special operation areas, resulting in a more standardized personnel management order.

Chemical Industry Park · Personnel Statistics

Park management data integration, full closed-loop emergency response

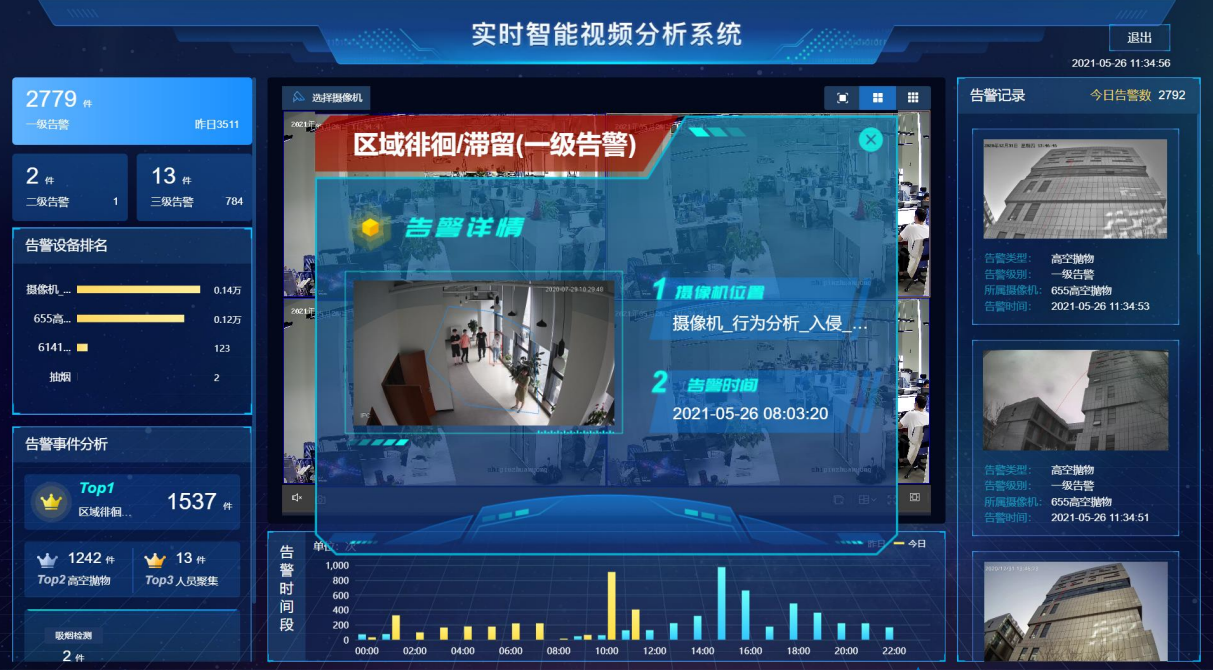

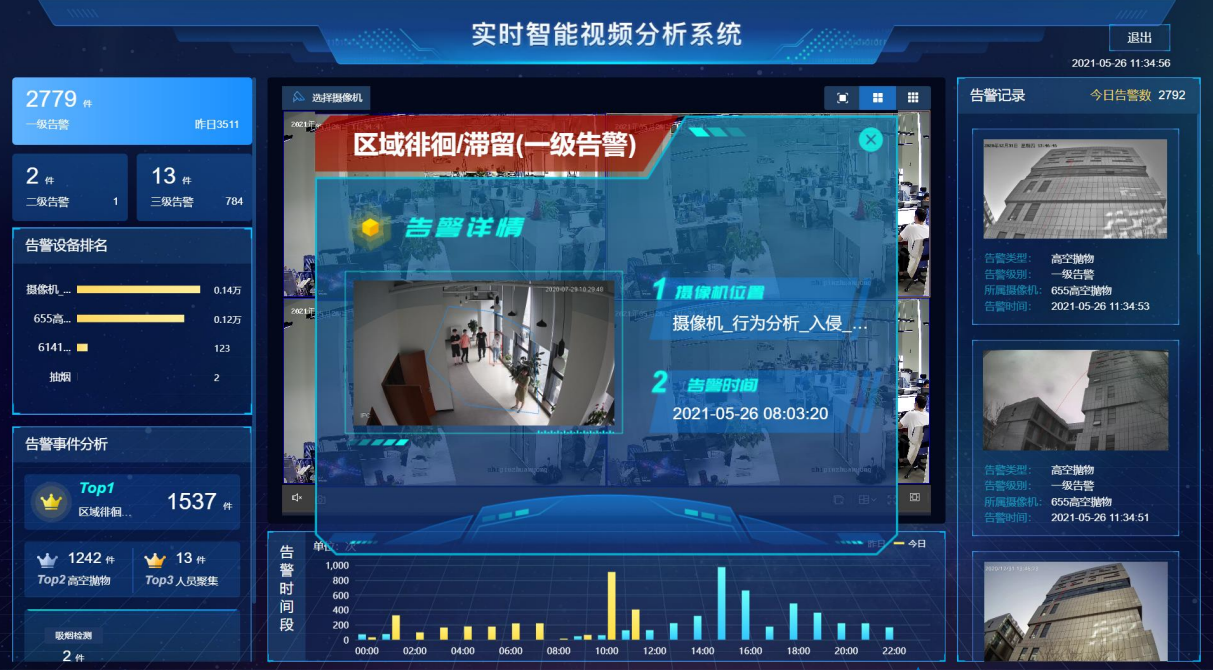

The Minivision AIoT digital intelligence service management platform has standardized applications such as global situation, video monitoring, and human vehicle deployment, which can be developed for secondary development and fully empower park scenarios.

The platform presents real-time dynamics of the park through data visualization. By connecting data interfaces, the government, enterprise, and emergency management departments can share the platform, achieving multi-party management, resource sharing, and information synchronization, and dynamic one screen control within the domain.

Chemical Industry Park · System Identification Abnormality, Sending Alarm

When a safety production accident occurs, the front-end camera immediately captures and interacts with the platform, providing alerts through various methods such as pop-up windows and phone calls, forming a complete emergency response loop of "production tracking, risk monitoring, hidden danger investigation, real-time warning, and linkage response", comprehensively improving safety governance capabilities and emergency management efficiency.

Real experience continuous scene landing

Minivision has deployed a smart park AIoT management platform for China Mobile Internet of Things, as well as intelligent hardware such as facial recognition access control and visitor planes, to manage nearly 10000 hardware devices.

In the Northeast region, Minivision has carried out intelligent upgrades of government parks for a certain city, district, and county government, achieving refined and intelligent management of government agencies.

AI blessing, comprehensive empowerment. Artificial intelligence technology is illuminating the park and escorting production with its unique brilliance.