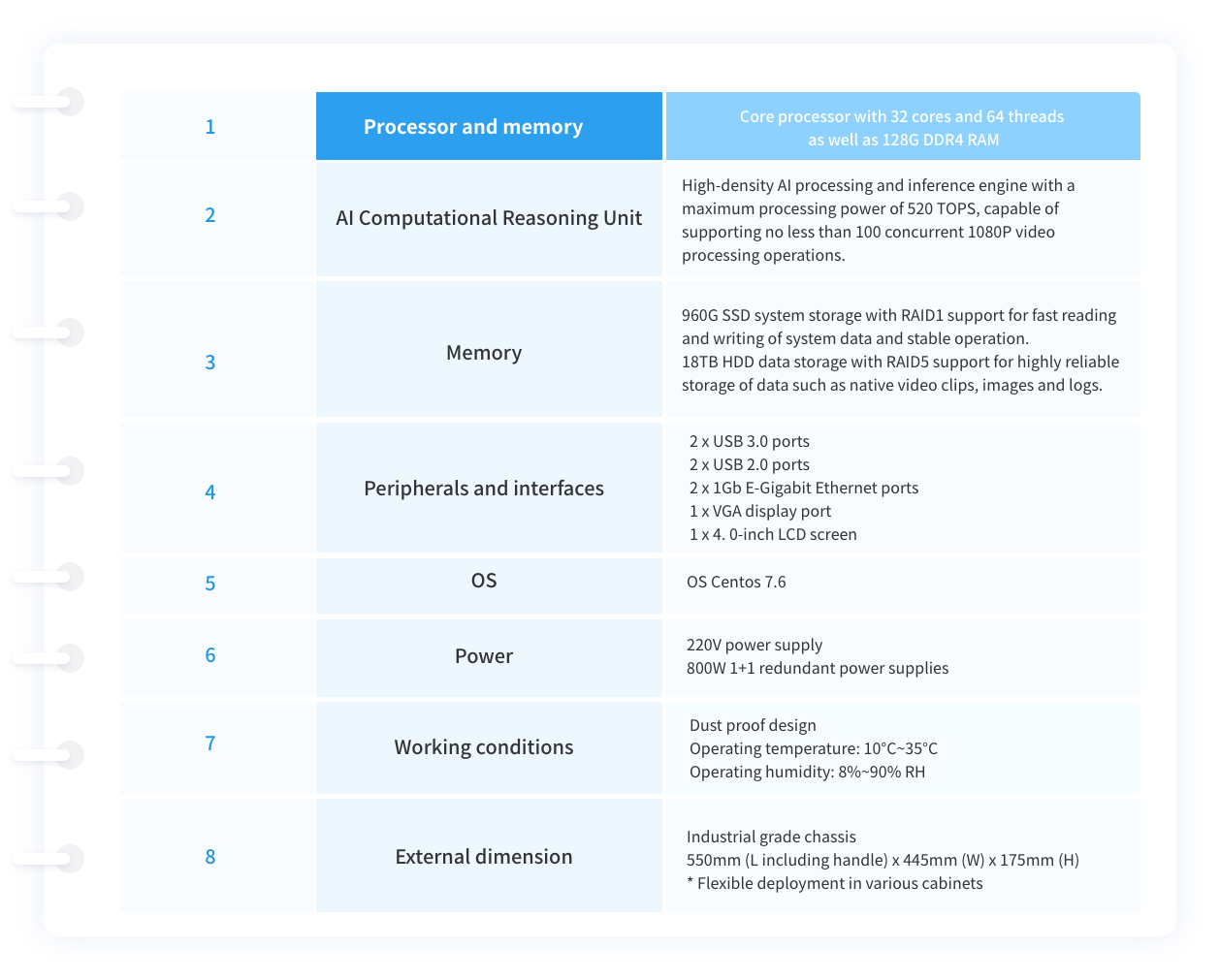

Minivision’s Lingque calculation and analysis integrated machine is an industrial-grade video computing integrated machine specifically designed for the mining industry. Its main purpose is to deeply understand mining scenarios, cover the full range of mining visual algorithms, and maximize the utilization value of computing power. It creates the "eyes of wisdom" for mines, detects risks and hidden dangers, and assists in mine safety supervision.

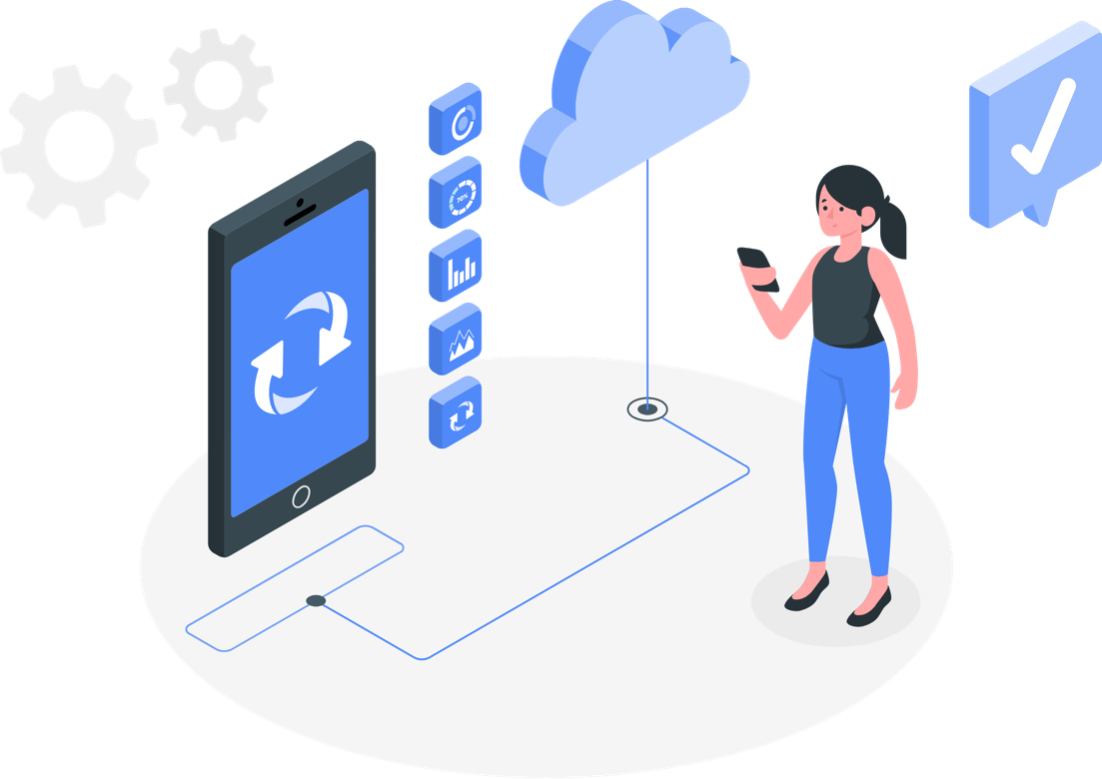

Based on AI and cloud-edge fusion technology, this device is equipped with built-in video analytics software that can analyze and calculate surveillance video in mining production scenes. It turns traditional surveillance cameras into safety inspectors, automatically identifying violations and risk events. Its features include video aggregation, intelligent analysis, risk alerts and event management.