The Minivision Lingque all-in-one application machine is specially built for coal mining enterprises. Focusing on "safety supervision" and "production management", for the three kinds of violations and risk events in open-pit and underground coal mines, it integrates "automatic inspection, identification, early warning, push, assessment" via video, and realizes the closed business loop of "automatic early warning, automatic push, automatic assessment". The application system of intelligent visual safety management in mines is constructed to assist coal mining enterprises to improve the quality of their safety management and increase the efficiency of their work.

Product Features

1)Real-time warning

Supports real-time video preview, alarm event pop-up window and voice prompt; Supports visual statistical display of alarm data, optimizes interactive experience, and improves business efficiency.

2)Real-time video

Supports video preview, playback, screenshots, recording, split screen, stream switching, PTZ control, etc., helping users easily control and manage camera monitoring status; Supports video cascade aggregation.

3)Video patrol

Supports orderly patrol and inspection of scenario videos according to the established sequence and time, generates inspection reports, reduces the pressure of on-site inspection work, and improves business management efficiency.

4)Event center

Collects alarm records to facilitate users to view and retrieve; Supports cascade aggregation of alarm events, hierarchical and classified push of alarm data, and linked processing of alarm events to improve business processing efficiency.

5)Attendance assistance

Support analysis of separation/disengagement status and improve on-duty rate and duty rate; Supports multi-shift scheduling and check attendance records;

Supports data review and correction, and can export statistical reports.

6)Four-color management

According to the four security risk levels of higher risk, high risk, general risk, and low risk, the key points of the enterprise are configured in a four-color grid of red, orange, yellow, and blue, and early warnings are pushed according to the risk level, and the treatment is classified and classified. , to help enterprises achieve refined management.

7)Data dashboard

Supports data aggregation and analysis overview; Supports detailed display of business data (drill-down) and cross-system coordinated processing of business data; Realizes enterprise managers’ one-screen overview and one-screen unified management of the status and results of three kinds of violations framework construction.

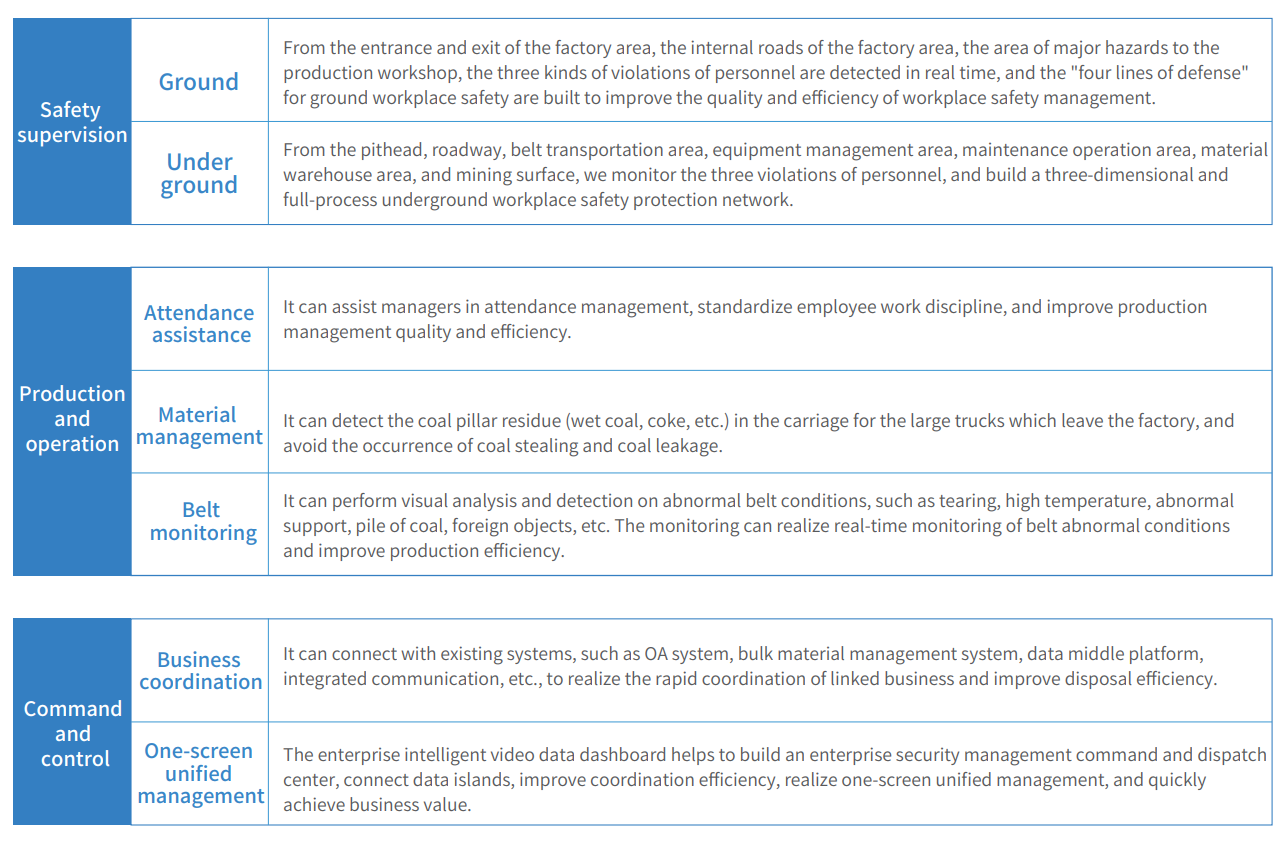

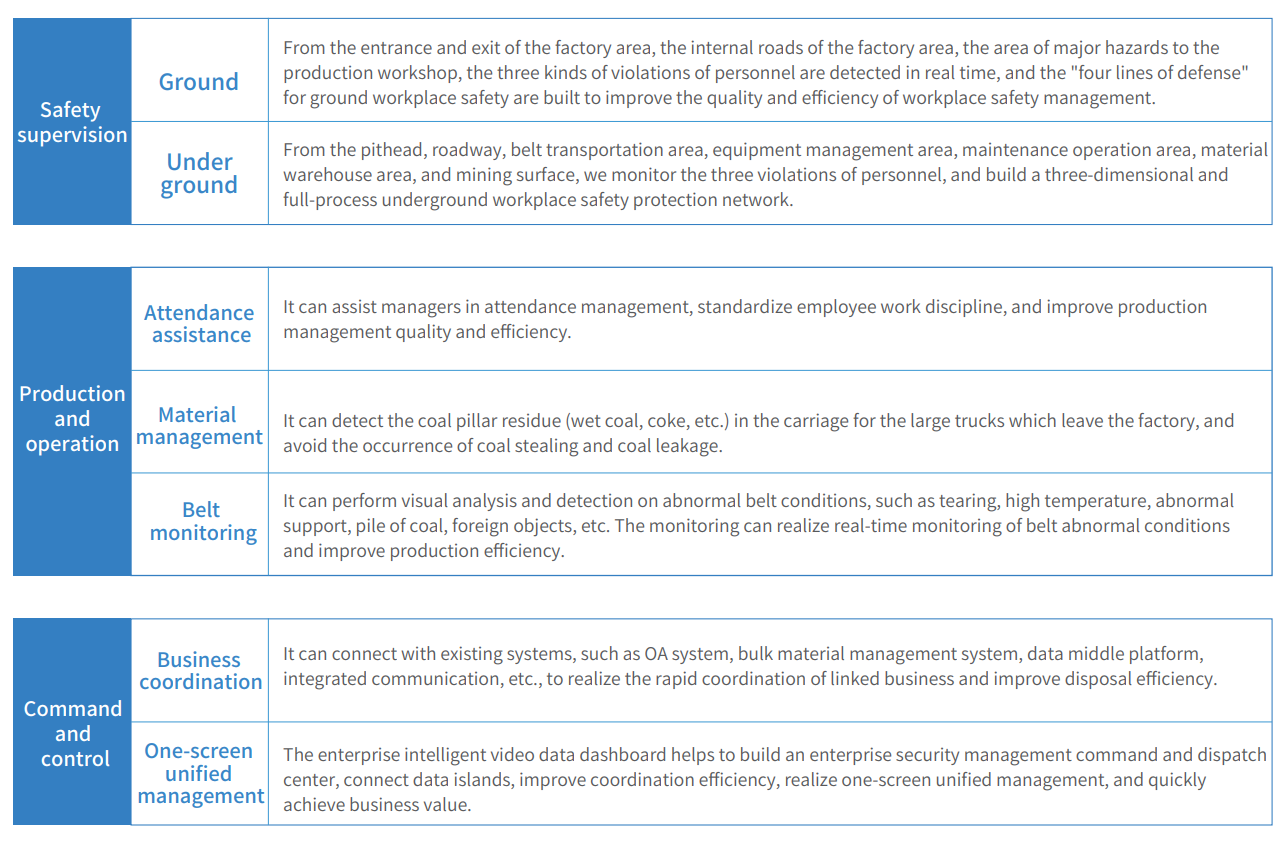

Covered Scenarios

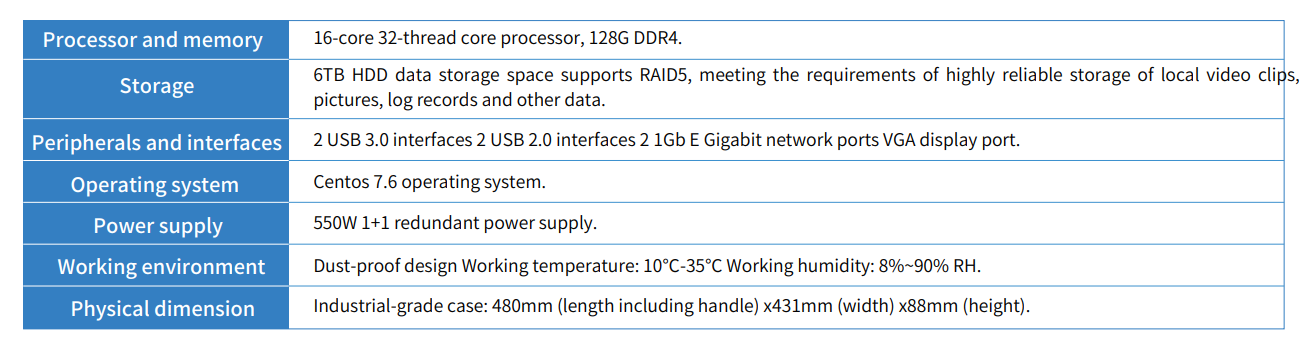

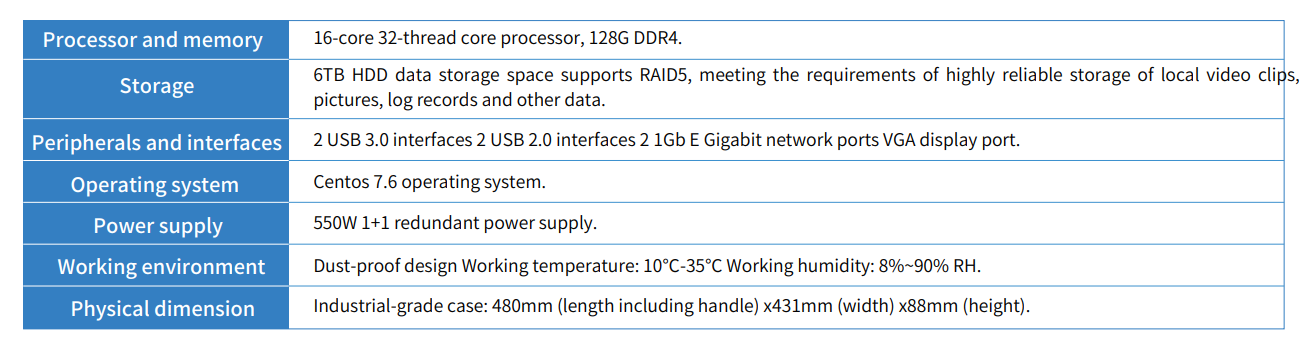

Product Parameters

Core Advantages

1)Effective scenarios

It can actively monitor the three violations of personnel in open-pit coal mines and underground coal mines, with high algorithm accuracy and good adaptability; It reduces labor costs and boosts management efficiency; It has been deployed in multiple mining factory parks and the application continues to expand.

2)Closed business loop

Through the integration of "automatic inspection, identification, early warning, push, and assessment" into one, inspection rules, inspection events, early warning levels, push methods, assessment system connection, etc. can be customized to realize a closed loop of safety supervision business.

3)Strong scalability

It has scalable capabilities, such as artificial intelligence production platform ATP, Internet of Things platform, streaming media platform, etc., to adapt to the needs of different customers.

4)Three-dimensional intuitive presentation

The platform integrates 3D maps (models), VR/AR real scenes, and large-screen scene data. The user interface is simple and easy to use, realizing one-screen unified management and one-screen overview of mine safety management and meeting business presentation needs

Value of Customer

1)Intelligent risk warning

The product comprehensively covers mine workplace safety scenarios, improves the effectiveness of video surveillance utilization by AI means, and realizes unmanned monitoring and early warning of risks and hidden dangers for 7*24 hours.

2)Reduce downtime losses

Real-time monitoring and analysis of risk factors such as personnel, equipment, and the environment can enable the detection of risks in a timely manner, accurate location of hidden dangers, and reduction of the loss of abnormal production shutdown caused by factors such as personnel, equipment, and the environment.

3)Achieve cost reduction and efficiency increase in management

We conduct in-depth exploration of the enterprise's production operation process to form a closed-loop business process mechanism for automatic inspection, identification, early warning, push, and assessment, effectively reducing management costs.