In recent years, the Chinese government has attached great importance to the intelligent construction of coal mines and has successively introduced relevant policies.

In February 2020, the National Development and Reform Commission and the National Energy Administration of China jointly issued the "Guiding Opinions on Accelerating the Intelligent Development of Coal Mines", which pointed out that by 2035, various types of coal mines will basically achieve intelligence, build a multi industry chain, multi system integration coal mine intelligence system, and build an intelligent perception, intelligent decision-making, and automatic execution coal mine intelligence system.

In December 2021, the National Energy Administration issued a notice on the "Trial Implementation of Management Measures for Intelligent Demonstration Coal Mine Acceptance", emphasizing the improvement effect of intelligence on coal mine production efficiency and safety level.

Shanxi Province, as a major energy province, is accelerating the intelligent construction of coal mines in various regions. In May 2020, the Shanxi Provincial Government launched eight

The department jointly issued the "Implementation Opinions on the Intelligent Construction of Coal Mines in Shanxi Province"; In March of this year, the Energy Bureau of Shanxi Province issued the "No.1 Document" for 2023- a notice on the "Work Plan for Accelerating the Construction of Intelligent Coal Mines in the Province in 2023", requiring the synchronous promotion of the "two transformations" of the coal industry, promoting the integration of data and reality, and the empowerment of data and intelligence. The intelligent construction of coal mines has shifted from a focus on mining working faces to the intelligent construction of the entire mine.

Promoting Intelligence: What Pain Points Should AI Accurately Solve?

Currently, there are four core pain points in safety management for mining enterprises. Firstly, the efficiency of manual surveillance is not high, the intelligent video analysis ability is insufficient, and there are large loopholes in video supervision; Secondly, the production environment of mines is complex and variable, and the supervision of standard operations is weak; Thirdly, business applications are fragmented and isolated, resulting in low efficiency in command and linkage; Fourthly, there is a lack of closed-loop management in risk management, resulting in high investment in management costs for mining enterprises.

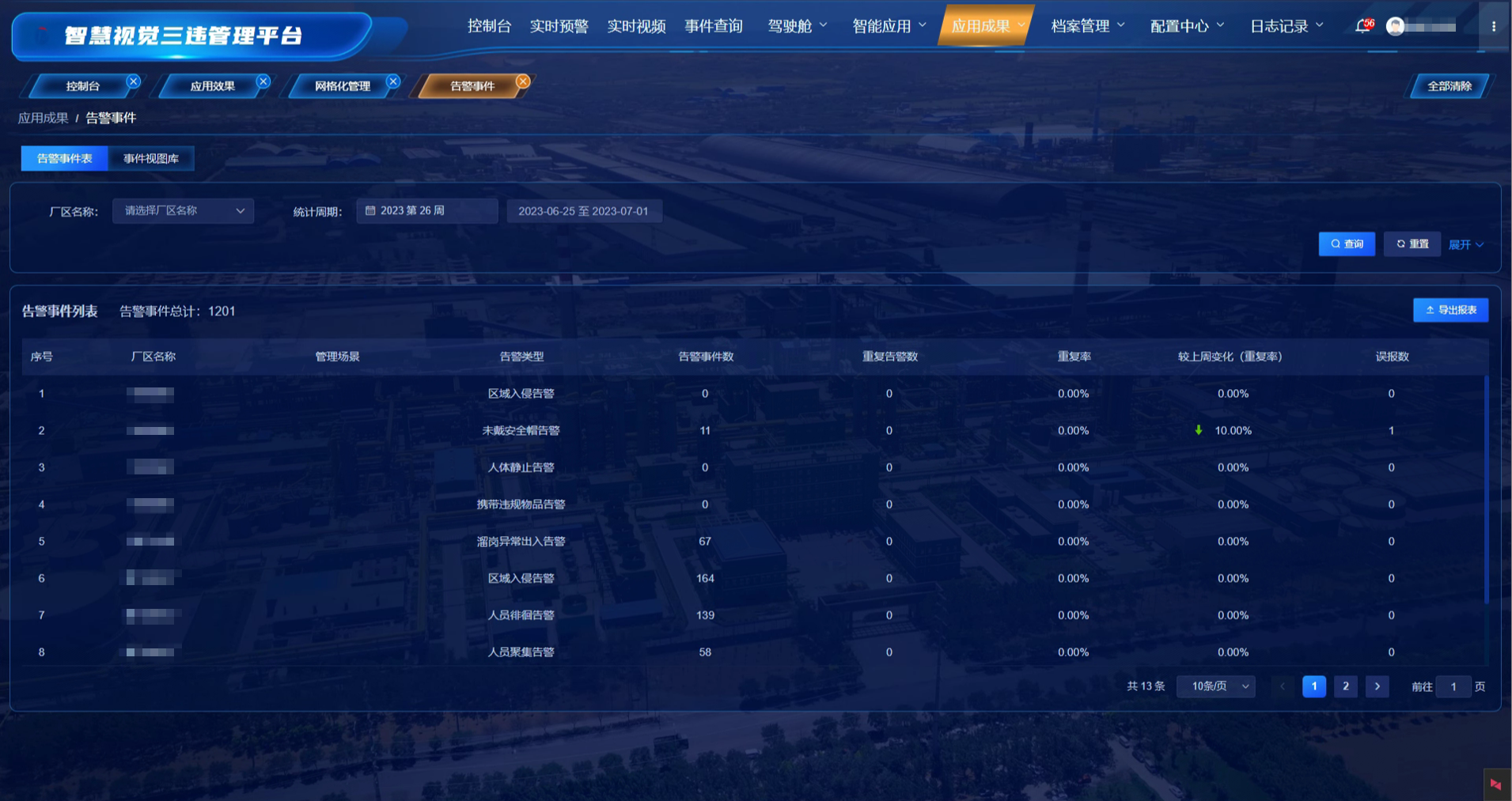

Minivision Technology Construction Plan for the Mine Smart Visual Management Platform for Three Kinds of Violations

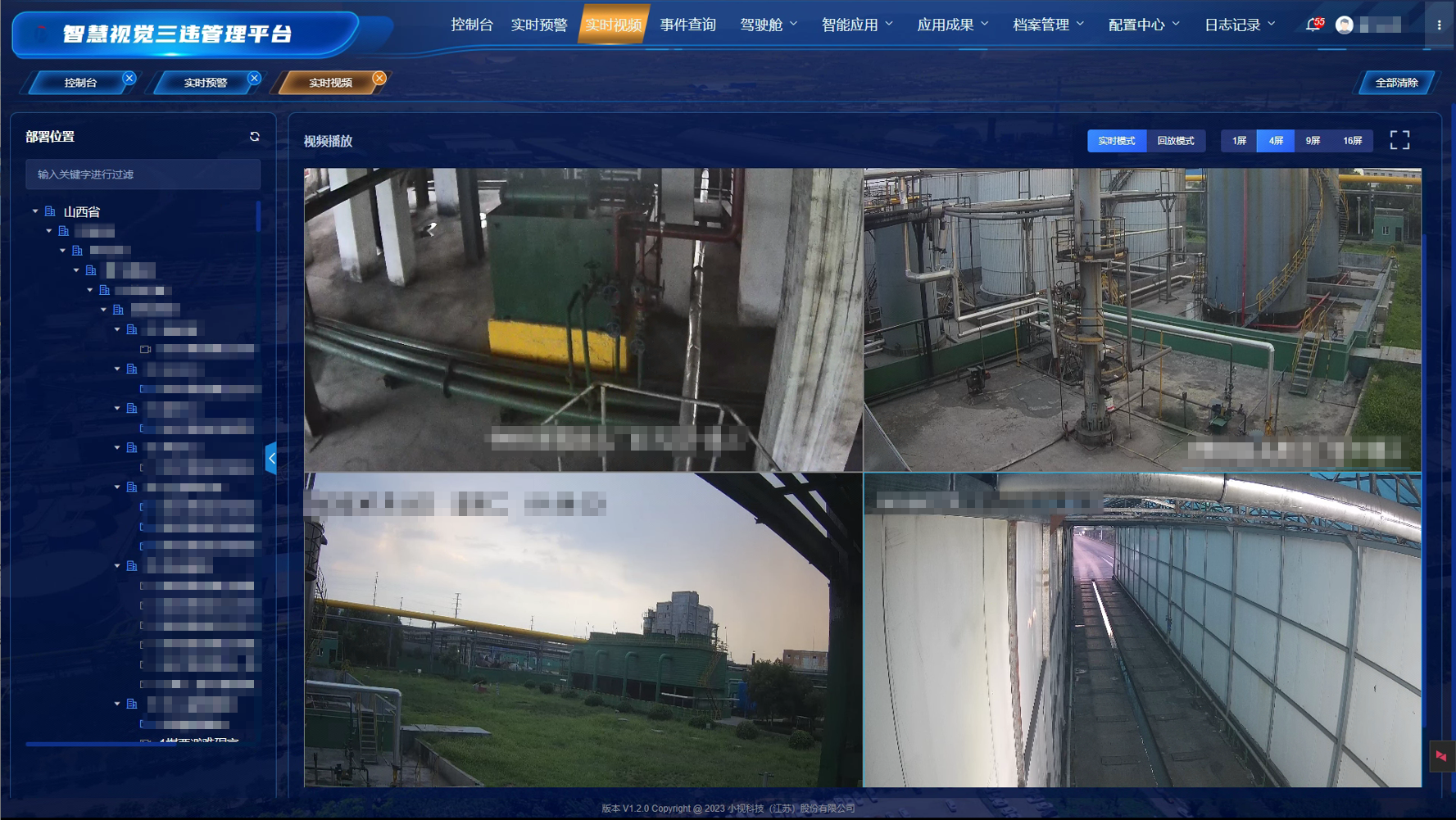

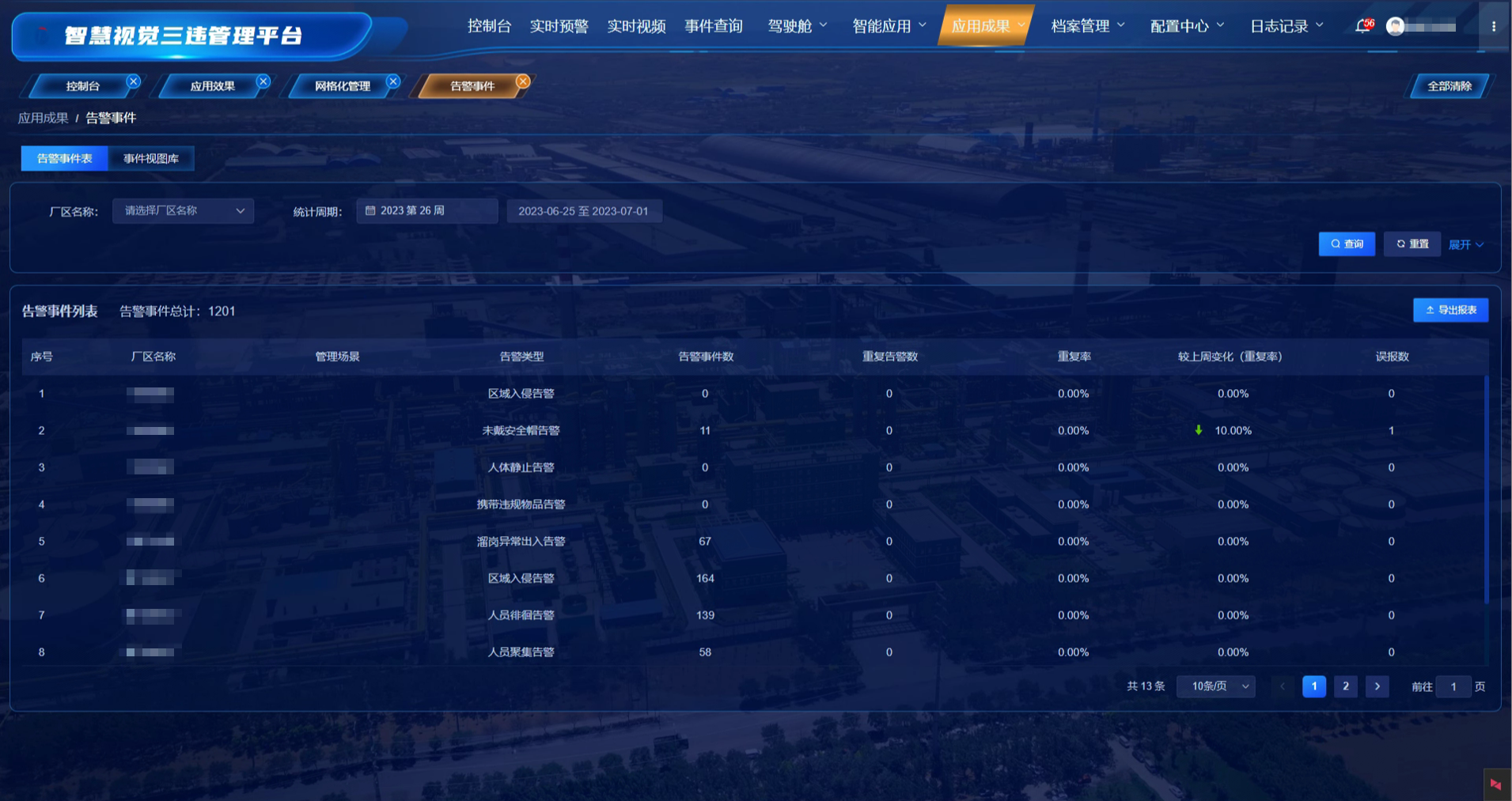

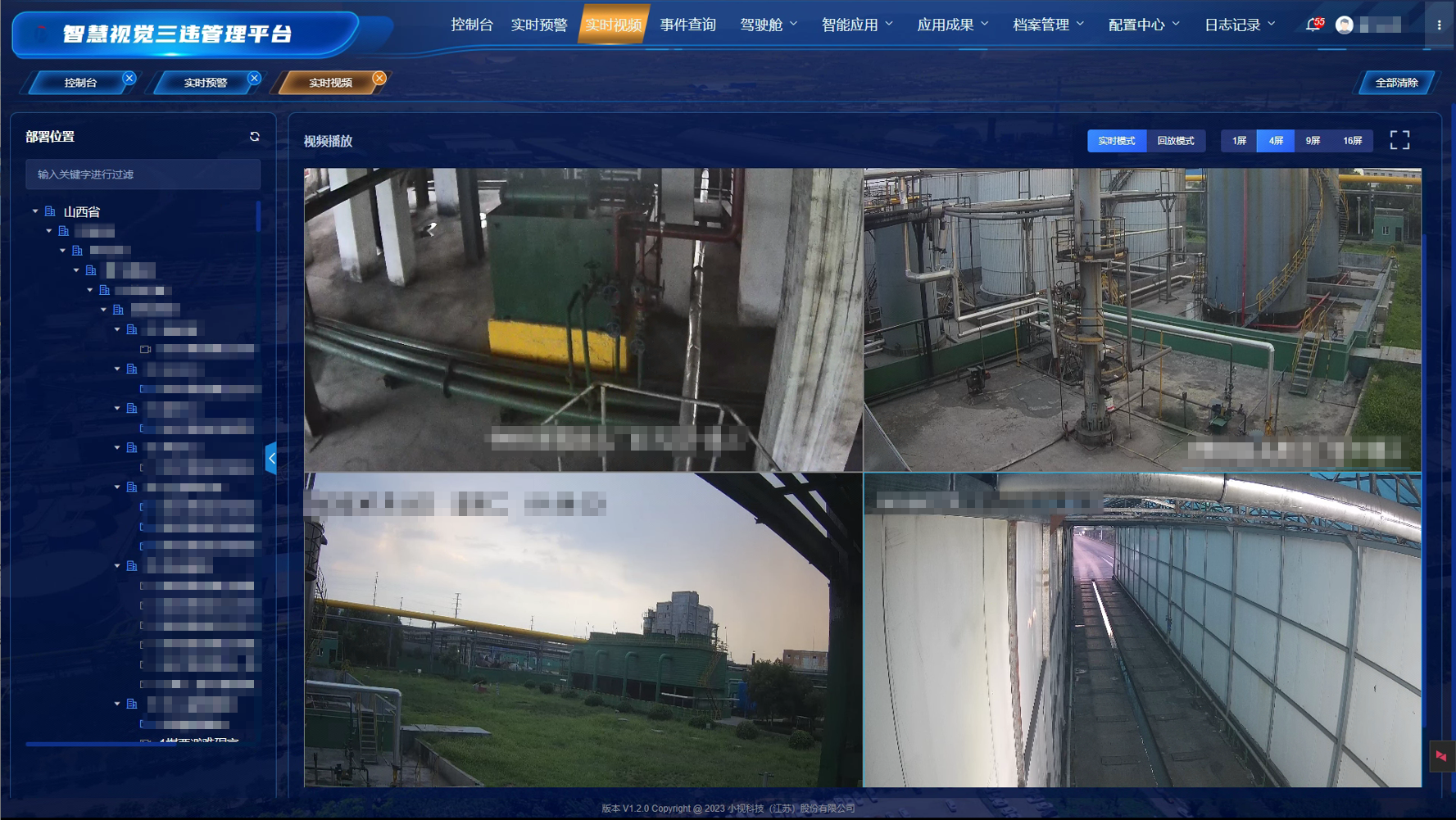

Minivision Mine Smart Visual Management Platform for Three Kinds of Violations targets coal mines and coal chemical enterprises. Based on AI video analysis technology, it provides image and video analysis and

real-time monitoring of three kinds of violations. By integrating five aspects of "automatic inspection, identification, early warning, push, and assessment" through video, we build a closed loop for the whole process of safety management, and create a digital and intelligent safety production management system for enterprises.

PRODUCT FEATURES

1)Product Features:It fully covers the underground and underground scenarios of workplace safety, realizes 7*24 unmanned monitoring and early warning of risks and hazards of "three kinds of violations", supports pop-up windows and voice

prompts for alarm events, and improves the efficiency of video surveillance with AI means.

2)Video inspection:It supports orderly scenario video patrol and inspection according to the established sequence and time,

generates inspection reports, reduces the pressure of on-site inspection work, and improves business management efficiency.

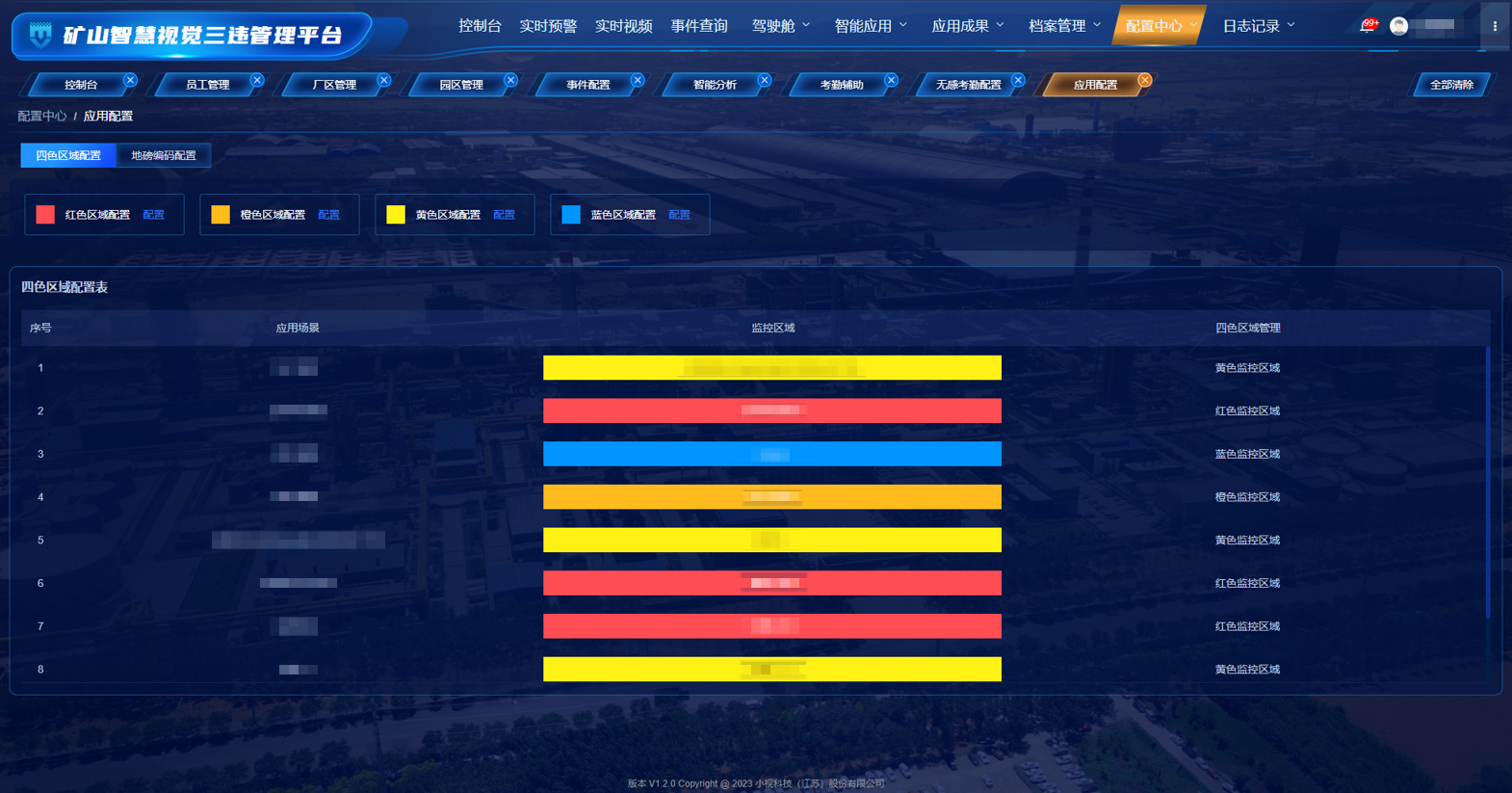

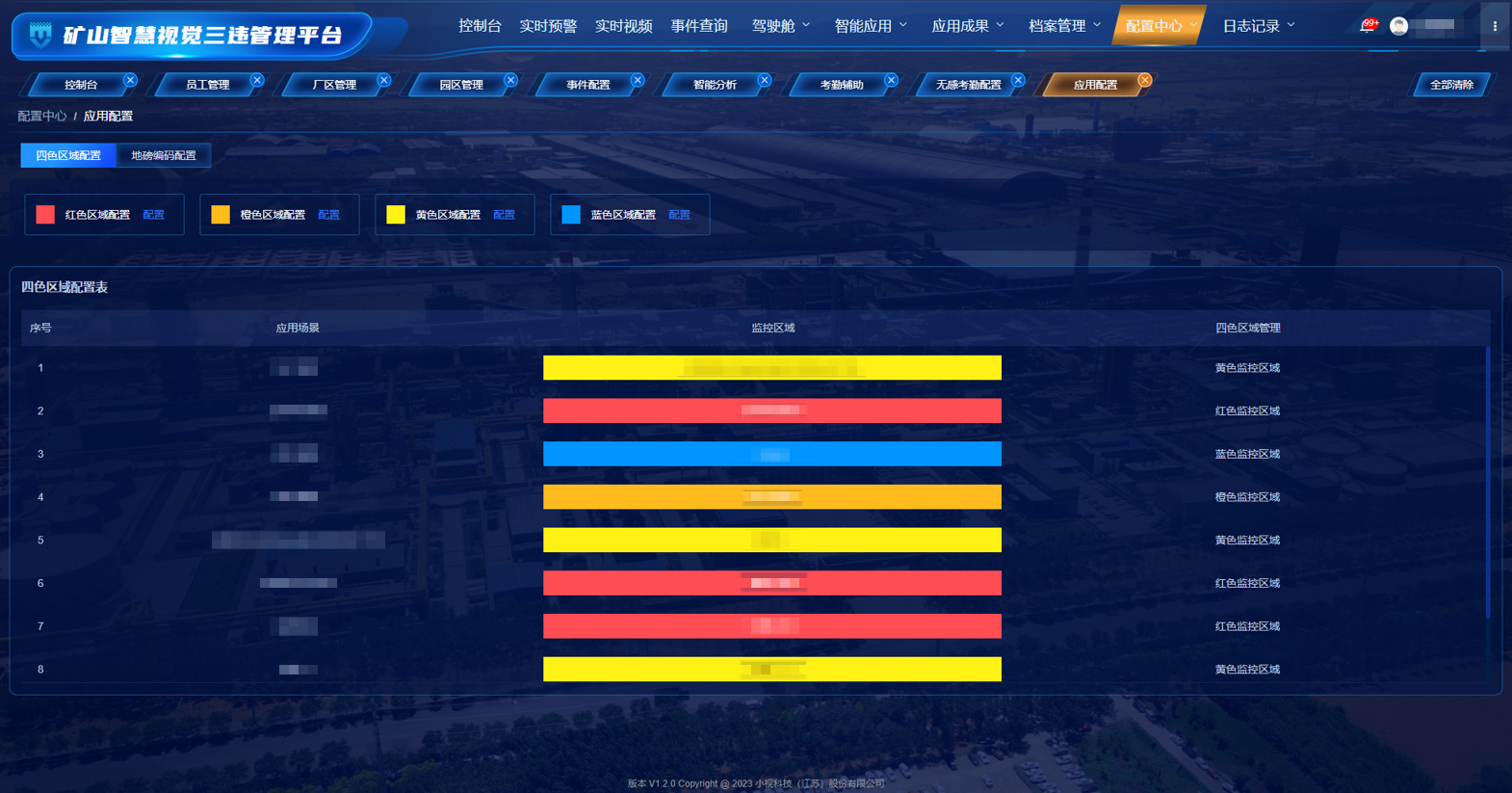

3)Four-color management:According to the four levels of higher risk, high risk, general risk, and low risk, key points are configured in a four-color

grid featuring red, orange, yellow, and blue, and early warnings are pushed and dealt with in a hierarchical and

classified manner to help enterprises refine their management.

4)Business cascade:We can collectively manage the video intelligent application business system of the group and its subordinate production units, and

adopt a distributed architecture design to support video cascading, data cascading, and application cascading between the group and

its subordinate units, improve the efficiency of the coordinated work between upper and lower-level units, and promote the rapid

achievement of business value.

5)Closed business loop:It can support a complete closed business loop including the functions of "automatic alarm, automatic push,

and automatic assessment"; Under the two-level architecture, it supports closed-loop business at all levels,

reduces network construction costs, avoids business interruption risks caused by network fluctuations, and

promotes the rapid achievement of business value.

6)Data dashboard:It supports the aggregation and analysis overview of achievement data and business data; It supports detailed display of

business data (drill-down) and cross-system coordinated processing of business data; It can realize enterprise managers’

one-screen overview and one-screen unified management of the status and results of the system of three kinds of violations.

A full-scenario visual capability service platform

for mines driven by application value

With the core goal of deeply understanding mining scenes, covering all mining visual algorithms, and having great value in computing power utilization, we aim to create a mining full scene visual ability service platform, identify and analyze mining videos and images, gain insights into mining safety, and assist in mining safety management.

1)Computing Power Scheduling.Through video patrol, tidal

scheduling and other

modes, computing resources

can be saved by more than 5

times.

2)Algorithm Configuration. The configuration algorithm

can be customized accord�ing to different camera

requirements, and

multi-edge drawing is sup�ported. The algorithm can

be used and replaced at any

time.

3)Load Balancing.It supports localized servers such as

Lenovo, Inspur, Huawei, Sugon, etc.,

and unified management of hetero�geneous resources such as GPU,

NPU, FPGA, etc. to fully utilize the

old ones; Computing resource

quotas can be dynamically adjusted

and allocated flexibly.

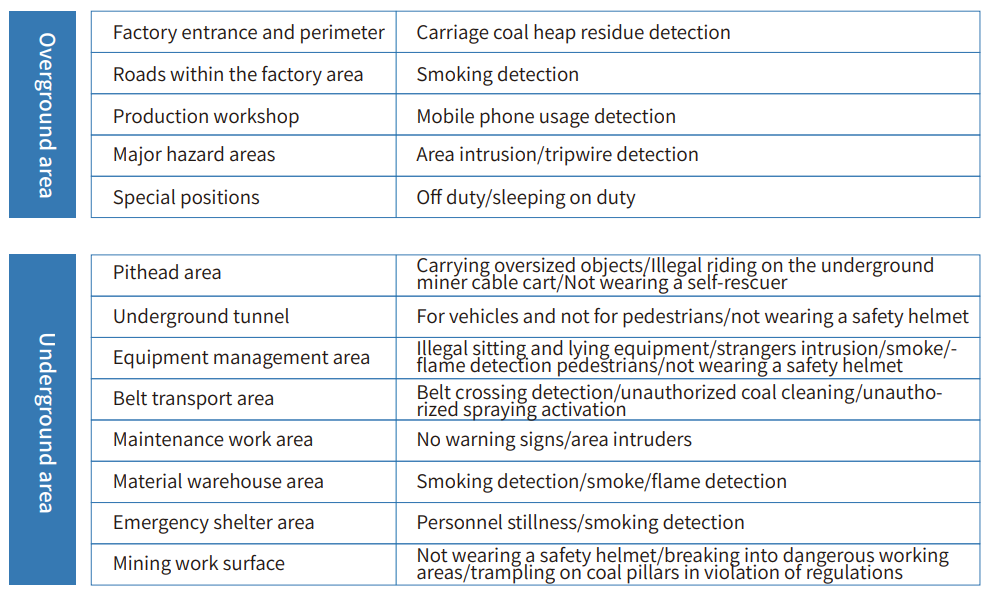

Scenario algorithm

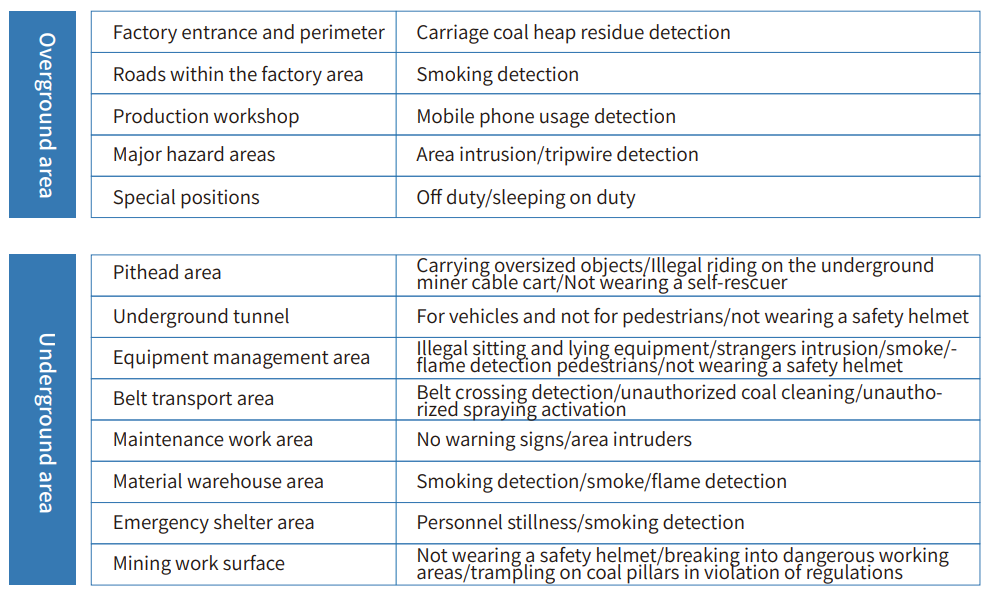

The key to implementing AI applications in mines lies in the scenario.

The platform currently supports over 70 types of work scenarios in open-pit coal mines and underground coal mines, with a wide range of algorithms and high accuracy, and the scenarios continue to expand.

Business closed-loop: automatic warning, automatic push, and automatic assessment

1) Intelligent video inspection. Flexible inspection strategies can be developed, supporting the setting of round inspection rules (specific time periods, inspection areas, etc.), achieving automatic inspection and duty in specific or key areas, and regularly generating reports.

2) Rich alarm methods. Support multiple methods such as system pop-up, voice linkage, WeChat/SMS/phone, etc.

3) Open docking capability. The platform architecture is open and supports docking with third-party business systems such as enterprise OA and data center, achieving a full closed-loop.

Data dashboard: building a digital sandbox for safety management, command and dispatch

The data cockpit has functions such as 3D real scene fusion, high point eagle eye monitoring, and can also gather information such as human vehicle situation, alarm event situation, equipment and facility situation for business auxiliary management.

CAPABILITY DEVELOPMEN

1)Covering video networking scenarios, it can connect to existing video platforms

and unify business entrances.

2)We provide modules such as annotation training platform and algorithm ware�house, build full-stack AI capabilities from data annotation, model training, model

deployment, operation, etc., and develop capabilities for large-scale enterprise

intelligent vision hubs.

3)It supports access to the IOT platform and builds industrial Internet of Things

capabilities.

4)We collect data from multiple dimensions, transform and upgrade application

platforms and data middle platforms.

VALUE OF CUSTOME

Artificial intelligence continues to empower the transformation and upgrading of mines, which can bring safety and efficiency in production, reduce personnel and increase safety, and is more likely to move towards unmanned production in the future.

The construction plan of Minivision Technology's intelligent visual three violation management platform for mines highlights its value in three aspects:

1)Intelligent risk warning:Comprehensively cover mine safety

production scenarios, we use AI

intelligent means to improve the

efficiency of video surveillance

utilization, and achieve 7*24

unmanned monitoring and early

warning of hidden risks.

2)Reduce downtime losses:Real-time monitoring and analysis

of risks of personnel, equipment,

environment and other factors, and

timely discovery of risks, precise

location of hidden dangers, reduce

the abnormal production shutdown

losses caused by personnel,

equipment, environment and other

factors.

3)Management cost reduction

and efficiency increase:We explore in depth the enterprise's

production operation process to

form a closed-loop business process

mechanism for automatic inspec�tion, identification, early warning,

push, and assessment, thereby

effectively reducing management

costs.

MODEL CASE

Minivision Mine Smart Visual Management Platform for Three Kinds of Violations has been gradually implemented and applied in many secondary units such as coal mines, coking plants, and methanol plants under Shanxi Pengfei Group, promoting the safety management of mining enterprises to gradually move towards "intrinsic safety".

In the following exploration, Minivision will also accelerate the construction of a large mining model based on more scenario sample data, focus on industry scenarios, solve mining safety regulatory problems, and create more AI application value.

At the same time, Minivision Technology will also cooperate with the entire industry chain of upstream and downstream mining, making the integration of AI and mining more closely, and enabling the power of technology empowerment to be meticulous and perfect.