In August 2022, the "14th Five Year Plan for Mine Safety Production" was issued, proposing to achieve the planning goals of making the safety prevention and control system more scientific and significantly improving the level of informatization and intelligence. In October 2022, the State Administration of Mine Safety and the Ministry of Finance specified in the "Overall Plan for Major Disaster Risk Prevention and Control in Coal Mines and Key Non coal Mine Mountains" that "AI Video Intelligent Auxiliary Supervision and Supervision System", "Emergency Response Video Intelligent Communication System", and "Intelligent Identification and Analysis System for Major Illegal Acts" should be constructed. Nowadays, achieving the goal of "intelligent perception, intelligent push, and intelligent decision-making" in the production, operation, and management of coal mining enterprises has become the key to the digital and intelligent upgrading of the coal mining industry.

Shanxi Pengfei Group is a digital, intelligent, and circular full industry chain main enterprise that integrates coal, coke, chemical, and hydrogen energy industries. It has now developed into one of the top 500 Chinese enterprises. Minivision Technology adheres to the value concept of combining scenario and AI, and collaborates deeply with Shanxi Pengfei Group around the coal coking scenario. With safety as the goal, Minivision Technology cooperates with various enterprises in the group to use video analysis technology to avoid three types of violations in mining production, prevent safety production risks, and jointly explore the value of smart visual technology in the management of three types of violations in coal coking enterprises.

Scenario driven, AI enabled

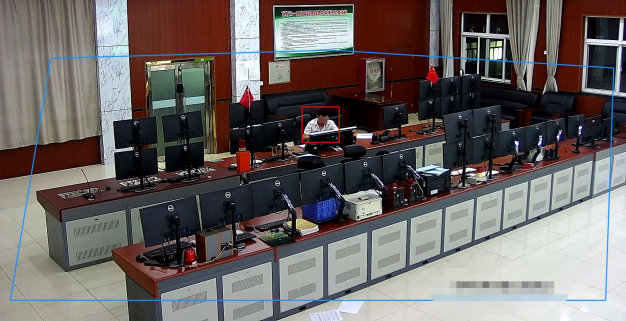

The intelligent visual "three violations" management platform utilizes existing and newly built video monitoring equipment to intelligently identify elements such as people, objects, behavior, and environment in the video, automatically detect abnormalities such as personnel's "three violations" behavior, equipment status abnormalities, and potential risks in the production environment, and actively trigger alarms. According to the needs of enterprise production management, further expand the application scenarios of AI intelligent visual analysis technology, gradually enrich and improve scene algorithms, and improve the quality and efficiency of mining safety production.

1) Implement intelligent identification of common violations in various production scenarios. For various scenarios on the ground and underground, achieve identification without wearing safety helmets, smoking, personnel off duty sleeping, playing with mobile phones, illegal entry into major hazard areas, and identification of overcrowding in production and operation areas.

Intelligent recognition without wearing a safety helmet

Smoking alarm

Off duty alarm

Recognition for playing mobile phones

Intelligent recognition of personnel falling

Intelligent recognition of personnel intrusion in major hazard source areas

2) Realize intelligent recognition of specific behavioral norms in production operation scenarios. Intelligent analysis of personnel carting regulations in sub wellhead and parking lot scenarios, actively identifying non-standard behaviors, and improving staff safety awareness. Conduct real-time analysis on behaviors such as non-compliance with ride management regulations, playfulness, intentional large swings, and carrying oversized or oversized objects in monkey car riding scenarios, and standardize personnel's ride behavior. For underground pedestrian and vehicle traffic management scenarios, intelligent identification of personnel and vehicles under the "pedestrian not driving, not driving" regulations and intelligent detection of vehicles to avoid non-standard operation of pedestrian driving. Conduct testing and analysis on the behavior of underground workers sitting and lying on cables and electrical equipment, strengthen on-site management, and ensure the safety of personnel and equipment.

Riding underground miner cable cart cars not standardized

Analysis of substation inspection trajectory

Abnormal intrusion into the chamber

Driving failure detection alarm

3) Realize intelligent identification of production scenarios such as underground main coal flow transportation. Real time monitoring is carried out for violations such as belt deviation, foreign objects in the belt, belt tearing, abnormal rollers, local high temperatures, personnel crossing violations, and handling floating/stacking coal during belt operation in the main coal flow transportation scenario, to ensure the safety of personnel and equipment during underground transportation. Conduct real-time monitoring of the underground belt conveyor head and water storage area around the clock, proactively detect and provide sound and light alerts on whether protective barriers and safety warning signs are installed, whether personnel have entered dangerous areas, etc., strengthen risk prevention awareness, and eliminate security risks.

Machine area personnel intrusion alarm

Large foreign object detection alarm

Carrier roller anomaly detection

Personnel crossing belt detection alarm

Integration of digital intelligence and business innovation

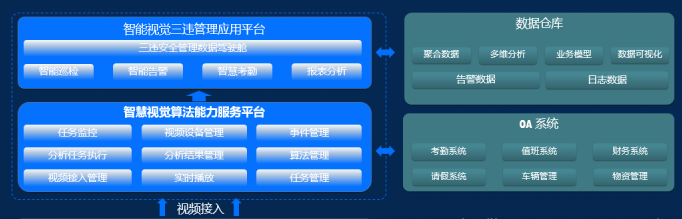

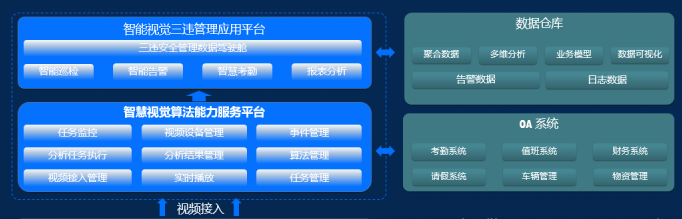

The intelligent visual three violation management platform serves as the intelligent visual service center of the group's data center, achieving deep integration of intelligent vision and data center.

In terms of serving the digital and intelligent business upgrading of the group's industry, the following three innovations have been achieved:

One is to achieve a closed-loop application of enterprise safety supervision business with "automatic warning, automatic push, and automatic assessment". Using intelligent visual three violation management events as the data source for enterprise security management, video events are unified into the group data warehouse. The data center is based on the current message push and management assessment mechanism used by the enterprise, achieving seamless connection between intelligent visual three violation management and enterprise operation management mechanism, while avoiding duplicate construction.

The second is to achieve grid management of "four color warning" for safety supervision. According to the safety risk management level, different production scenarios are divided into four color warning grid areas of "red, orange, yellow, and blue". The intelligent warning of three violations is integrated with time and space, and the risk level of the same type of event is related to the grid, achieving hierarchical classification and management of three violations and risk levels.

The third is to deeply integrate intelligent vision with data analysis. By comprehensively analyzing multiple dimensions such as equipment, algorithms, scenarios, behaviors, effects, and spatiotemporal distribution, we aim to achieve situational awareness and trend prediction of the risks of enterprise safety production three violations management, providing a digital and accurate decision-making basis for safety production management.

Paradigm innovation, creating a model

The innovative paradigm driven by scenarios has accelerated the value realization of artificial intelligence technology in scenarios. In terms of algorithm model research and development, a data annotation and algorithm training platform has been deployed in the group, achieving a technical closed-loop of sample data collection, annotation and algorithm model research and development, optimization, and effect verification, improving the efficiency of algorithm research and development and the speed of value implementation in scenarios. In terms of pilot promotion of new scenario models, a strategy of pilot first and then promotion is adopted. Research and optimization of new algorithm models, focusing on pilot scenarios, and conducting online upgrades for general production scenarios after full validation in pilot scenarios, effectively improving the research and development efficiency of new algorithm models and the application effect of mature algorithm models.

Since its launch, the intelligent visual three violation management platform for coal mining enterprises, based on Changxin Coal Mine as a model, has innovated over 20 visual algorithm models driven by scenario applications, serving multiple scenarios of "personnel three violations" safety supervision in coal mining enterprises, and achieving a transformation of video monitoring in safety production from traditional "people looking for information" to "information looking for people", Created significant management benefits and economic value for the enterprise.

Changxin Coal Mine adopts AI intelligent visual analysis technology and uses the personnel's three violations intelligent recognition system to investigate "three violations", practicing the advanced management concept of mine safety supervision in Shanxi Province and obtaining high recognition from industry regulatory units. This mature experience has played a promoting role in the digital and intelligent upgrading of coal mine safety production throughout the province, and will be promoted and learned throughout the province.