- Home

- Core Technologies

-

Product Center

- AI Labelling Training Platform

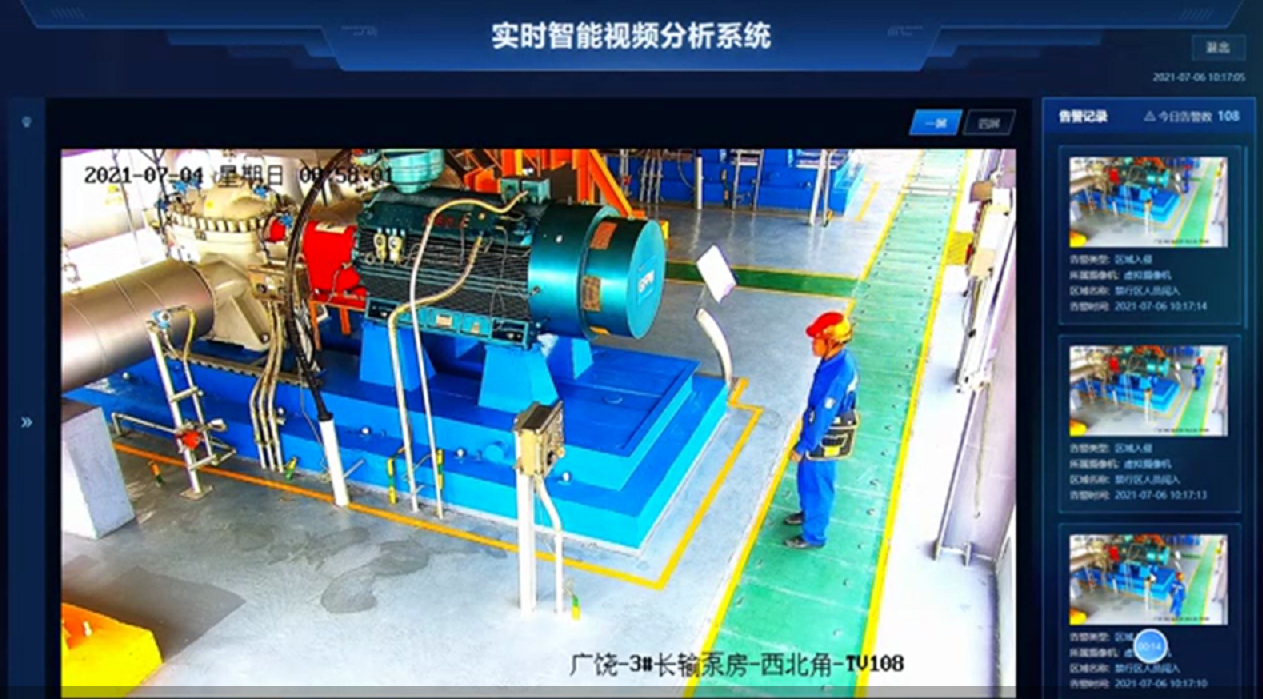

- AI Algorithm Set

- Visual Center Platform

- AIOT Platform

- High-performance and Low-latency Edge Computing

- Intelligent Mining Applications Integrated Machine

- Intelligent Mining Calculation and Analysis Integrated Machine

- Intelligent Terminal Engine

- Intelligent IoT Application System

-

Industry Applications

-

Digital Intelligence Living

-

Digital Intelligence Governance

-

Digital Intelligence Industry

-

Digital Intelligence Military Industry

-

- Eco-cooperation

- News Center

- About Us

- Open Platform

- 语言:中

The application solution is being upgraded

Stay tuned